Do Air Compressors Run Out of Air?

Yes Air compressors do run out of air and are essential equipment in garages, factories, and industrial shops. They can perform various tasks, from filling gas cylinders to providing high-pressure air. However, despite their ability to refill themselves, air compressors are prone to running out of air from time to time. In this article, we will explore the reasons behind this and discuss ways to prevent it.

What Causes Air Compressors to Run Out of Air?

There are several reasons why an air compressor may run out of air. The most common causes include:

- Air Leakage: Air leakage around the air compressor is a common issue that leads to unexpected run-out. It is often noticeable around the hoses and tank, and low air pressure is a clear sign of air leakage. Finding and sealing the leaks is the key to preventing air run-out issues.

- Loose Tube Fitting: Novice users sometimes make mistakes by attaching the tube fittings loosely. This can cause the air to escape without any noticeable signs. To prevent this, always tighten the tube fittings properly.

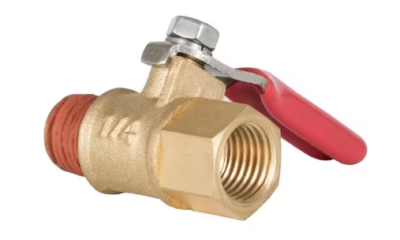

- Faulty or Leaky Valves: A damaged check valve can allow air to pass through the compressor, leading to unintentional run-out. Similarly, any leakage in the safety valve will prevent it from holding the air. Replacing these faulty components is necessary to eliminate air run-out issues.

- Compressor Leaks Air: If you shut down the compressor when the tank is filled with air and then notice a drop in pressure, it means the compressor is leaking air. Identifying and fixing the leaks is essential to maintain air pressure.

- Excessive Noise From the Compressor: Loud and obnoxious noises from the compressor may be due to loose parts, troubled crankcase, or problem pistons. Regular maintenance and tightening of parts can help reduce noise levels.

Keeping Your Compressor Running Continuously Causes Air loss?

While some suggest leaving the compressor running continuously, it is not the safest option for various reasons:

- Excessive Motor Wear: Continuous operation causes internal parts to wear out faster, leading to shorter equipment lifespan.

- Part Failure: Constant pressure in the tank can lead to catastrophic motor failure if a seal or hose fails. The cost of repairing a failed compressor can be high.

- Energy Waste: Running the compressor constantly wastes energy and increases operational costs.

- Moisture and Rust Buildup: Constantly pressurised compressors trap moisture, leading to rust and potential damage over time.

- Stored Energy: Over-pressurized tanks can become hazardous and pose a safety risk.

How Long Can an Air Compressor Run Continuously Without Air Loss?

The duration an air compressor can run continuously depends on its type. There are two primary types of air compressors:

1. Reciprocating Compressors

Reciprocating air compressors have a duty cycle that determines how long they can operate continuously. They work by compressing air with one or more pistons inside a cylinder. These compressors need time to cool down, and their duty cycle should be mentioned in the manual. Exceeding the duty cycle can cause damage to the compressor and air leakage.

2. Rotary Screw Compressors

Rotary screw compressors are more industrial-sized and designed for continuous use. They can run 24 hours a day, seven days a week, with minimal risk of mechanical issues. These compressors use spinning rotors to compress air, producing less heat and wear on mechanical components.

Conclusion

In conclusion, air compressors can indeed run out of air due to various issues such as air leakage, loose fittings, and faulty valves. Knowing the type of compressor you have and its duty cycle is crucial to preventing potential problems Proper maintenance and understanding your compressor’s limitations are essential to prevent it from running out of air and to ensure its longevity. Shutting off the compressor when not in use, emptying the pressure, and regular maintenance are crucial steps to keep your compressor in top condition for years to come.

Frequently Asked Questions

What happens when an air compressor runs out of air?

An air compressor problem could stem from one of many issues, such as an air leak, an oil leak, or a broken part. In some cases, you might have insufficient pressurization or air flow, which can be frustrating, costly, and time-consuming. Proper air compressor troubleshooting can often resolve these issues.

How much air does a compressor need?

The amount of air pressure needed for a given application depends on the air tools and their specific requirements. Portable air tools typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), while larger tools connected to stationary systems may require more than 10 cfm at 100 to 120 psi. Always check the cfm requirements of your tools and match them with the compressor’s rating.

How does air get compressed in a compressor?

Air compressors compress air by drawing it in through an inlet valve, compressing it to the required volume, and releasing the pressurised air through a discharge valve into a storage tank. There are two types of air displacement methods: positive displacement and dynamic displacement, each with its own compression process.

Shaleen is a Journalism postgraduate, and like every other gen-z, loves a good dose of humor, Italian food, fashion trends, and TV series. She is an acomplished author and expert in the field of air compressors. Shaleen discovered her passion for technical products and gadgets early in life, which drove her research and write about it.