how to build a water trap for air compressor

Compressed air is a widely used resource across numerous industries, powering everything from pneumatic tools to HVAC systems. However, as essential as it is, the process of compression can lead to the accumulation of moisture, which could potentially damage downstream equipment. To tackle this issue, the use of water separators, or ‘water traps’, is vital. In this article, we delve into the steps involved in constructing a water trap for an air compressor and explore some critical considerations for its application.

Air Compressor Water Trap Setup

Correctly setting up your air compressor, along with its auxiliary components, requires careful attention. Here are some essential factors to consider:

- Space: Your air compressor should be installed on a sturdy and level floor, with plenty of space around it for smooth airflow and maintenance.

- Ventilation: Ensure the area is well-ventilated for peak performance.

- Safety: Manage your electric cables properly for safety.

- Component Installation: When setting up your air filter and air dryer, make sure to check them before use. Run the air through the filter to ensure it is clean and dry.

- Auxiliary Tank: An auxiliary tank is a dedicated air receiver to service your air compressor, so it’s essential to install it correctly.

- Testing: Before fully using your air compressor, start it up to test for any possible malfunctions, like leaks.

Note: Always use certified installers to ensure your compressed air installation is compliant with local regulations, safe to operate, and as energy-efficient as possible.

Steps to Make a Water Separator for Air Compressor

If you’ve ever found yourself struggling to understand how to build a water separator, then fear not. The process is more straightforward than you might think. Here are nine easy steps to making a water separator for your air compressor:

- Joining the pipes: Start by joining three 2-inch copper pipes with a 90-degree copper elbow at each end. Make sure to apply a light coat of soldering flux inside the copper elbow and on the pipe’s outer side before fitting them together to prevent oxidation.

- Assembling the structure: Next, take three more 2-inch copper pipes and affix a copper tee to each one. Then add the leftover copper elbows to the other end of each pipe.

- Connecting the joints: Take the joint with the copper tee and join each of the three unused 2-inch pipes to it. The second 2-inch pipe should be the one joined to the copper tee.

- Attaching the long pipes: Using the joint with the copper tee, attach it to two 72-inch type L copper pipes. One of your joints should only be joined to a single long pipe, so ensure this is attached to the side of the structure with the copper elbow.

- Ensuring a smooth air flow: Attach the other joints to the other side of the type L copper pipes, ensuring there will be a continuous flow of air throughout the chambers. One of these joints will be attached to a single pipe.

- Soldering the joints: Heat the pipes at the joints using a propane torch and melt the solder on the pipe once it’s hot enough. A green flame on the pipe is a good indicator of a suitable temperature. The solder will be sucked inside the seam if the pipe is suitably hot, creating an airtight seal.

- Fixing the adapters: Fix three 3/4” -1/2” male adapters on each outlet at the bottom of the system and solder them to prevent leaks.

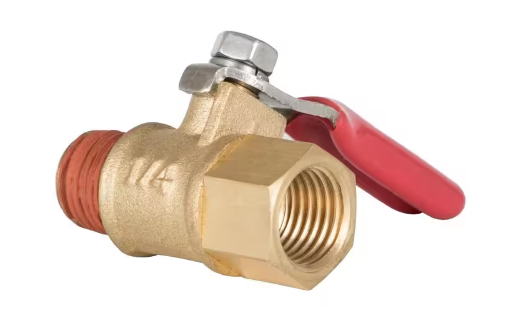

- Adding the ball valves: Next, add three threaded 1/2” ball valves below the male adapters. Use PTFE tape to create secure threading.

- Finalizing the setup: Lastly, cut the remaining 72-inch copper pipe into two halves and fix them on each side of the system. One side will be attached to the brass street elbow to go to the regulator, while the other side attaches to the compressed air hose coming from your compressor.

Automatic Water Separator for Air Compressor

For those seeking a less manual option, an automatic water separator can be an excellent choice. One such example is the ‘Trident Water/Moisture Separator – TFM’ which removes moisture from the compressed air by coalescence and drains the condensed water periodically via manual or automatic draining.

| Model | Drain Type | Flow Rate (cfm) | Max. Working Pressure | Port Size (BSP/NB) | Dimensions (mm) ABC | Weight (kgs) |

| TFM 72 | MD/EA | 45 | 16 kg/cm2 | 3/4″ | 255, 450, 400 | 7 |

| TFM 144 | MD/EA | 85 | 16 kg/cm2 | 1″ | 270, 570, 500 | 11 |

Conclusion

Building a water trap for your air compressor is not as complicated as it may seem. WithWhat is the purpose of a water trap on an air compressor? Water traps are essential for preventing water and condensation from entering the air tools attached to your air compressor. This is especially important when using the air compressor for applications that require dry air, such as painting or sandblasting. Not only can water damage the air tools attached to your compressor, but it can also interfere with the application at hand, potentially ruining your project. For these reasons, it is important to use a water trap with your air compressor, especially if you live in a humid area or are using the compressor for applications that require dry air. How do you remove water from an air compressor? Drain the Tank Regularly:

Frequently Asked Questions

1. Do you need a moisture trap on an air compressor?

While not a strict necessity, using a moisture filter is a good precaution to protect your tools from potential water damage, especially if you use your nailer infrequently in high humidity or store it for long periods.

2. What happens if you don’t drain water from an air compressor?

Failure to regularly drain water from your air compressor tank can lead to corrosion, potentially affecting the integrity of the tank itself over time. It’s recommended to drain the tank at least twice daily during heavy use.

3. Do air compressors collect water?

Yes, water gets separated from the compressed air during compression and can end up in air lines, receiver tanks, or pneumatic tools if not properly filtered out.

Shaleen is a Journalism postgraduate, and like every other gen-z, loves a good dose of humor, Italian food, fashion trends, and TV series. She is an acomplished author and expert in the field of air compressors. Shaleen discovered her passion for technical products and gadgets early in life, which drove her research and write about it.