How to Change Air Compressor Oil

Like other mechanical devices, air compressors require regular maintenance. Among these, changing the air compressor oil is crucial. This article outlines the process of changing your air compressor oil, taking into account various elements, such as the air compressor oil level sight glass, the components to identify on your compressor for oil change, the frequency of change, and so forth.

Step-by-Step Guide to Changing Air Compressor Oil

Follow the steps below to change your air compressor oil efficiently:

- Allow the compressor to warm: Like a car engine, the oil in the compressor will run easier if it’s warm. Let the compressor sit in the sun or let it run and fill the air tank before starting the job.

- Open the fill port: This allows air to flow more easily down into the sump.

- Position a funnel: Carefully open the drain plug and let the oil drain out. Be cautious as the oil might be hot.

- Lift the compressor: To void the sump of any residual oil, lift the front of the compressor.

- Replace the drain plug: Ensure to wipe any oil residue from the surface so you can detect any leaks.

- Pour in the replacement oil: Use fresh compressor oil and fill up to the specified level for your compressor.

- Replace the oil fill cap: Once done, your compressor is ready to use!

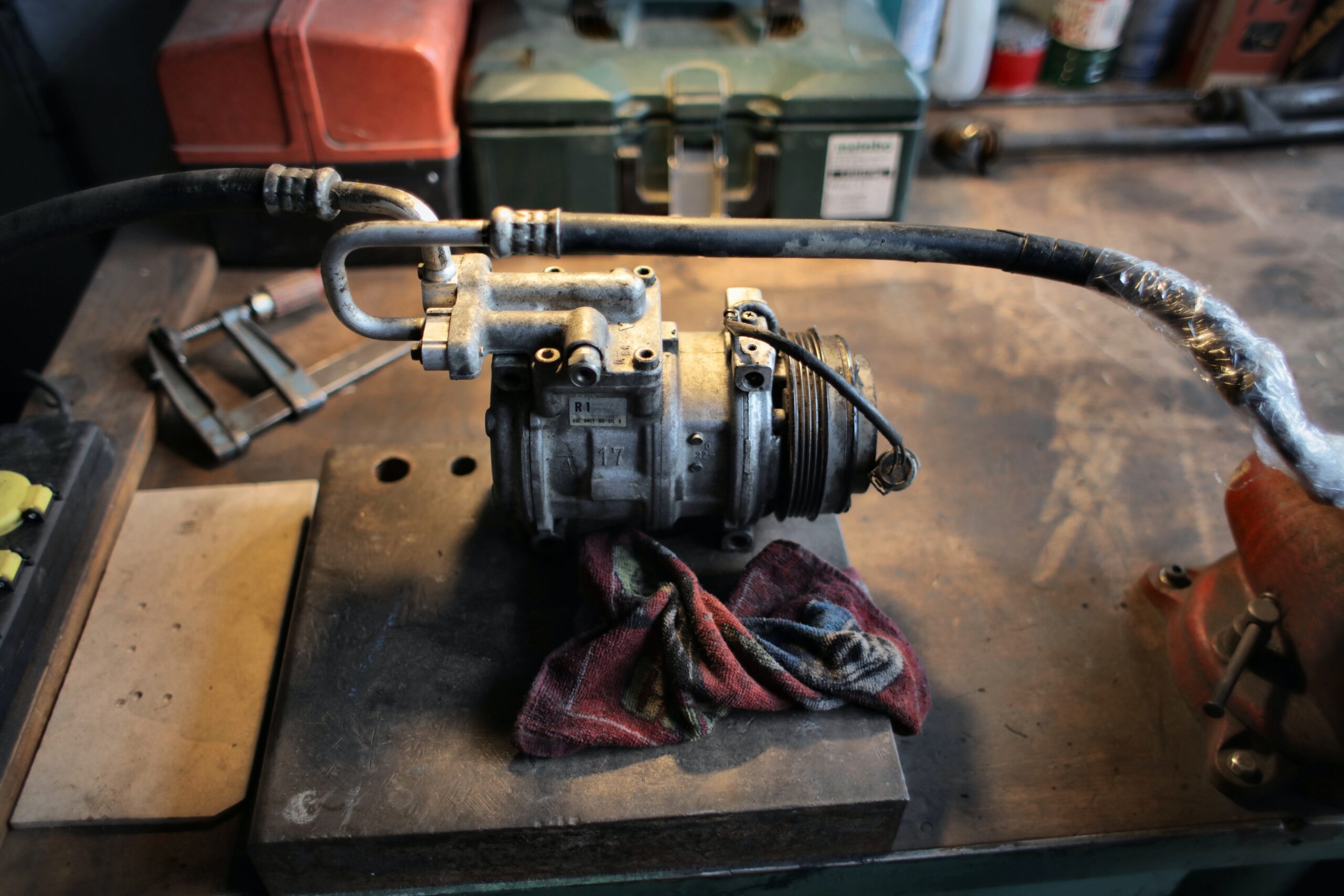

Identifying the Key Components for Oil Change

Oil Fill Port : This port, typically located higher than the oil drain port, allows oil to be poured into your compressor to flow down into the oil sump. It’s worth keeping a small funnel at hand to avoid oil spillage during the refill process. The cover for this port is usually vented to avoid a vacuum forming in the sump, which could limit the efficiency of the lubrication process.

Sight Glass : This feature allows you to view the oil reservoir and check the oil level. For most compressors, the oil level should be maintained at the center of the sight glass marker. Overfilling the oil sump can lead to maintenance issues, so ensure the level is correctly maintained.

The Oil Sump : Located inside the compressor casing, the oil sump’s size determines the amount of oil your compressor will need. Check the oil level every time you turn the compressor on to avoid running out of oil.

Drain Plug : Removing this plug lets the oil flow out of the sump. Make sure to place a reservoir or similar container under the drain to contain the oil and prevent spillage.

The Drain Plug: Draining the Old Oil

The drain plug is your gateway to removing old oil from the compressor. Proper draining requires removing the drain plug and allowing the oil to flow out from both the drain plug hole and the suction and discharge ports. Remember, the oil should be warm for easier flow, so consider running the compressor for a while before starting this process.

Sight Glass : Air Compressor Oil Level

The oil level sight glass is an essential component that allows you to check the oil level inside your air compressor. Most air compressors come with an oil sight glass made of stainless steel or aluminum alloy, located at the base of the pump or on the compressor sump tank. This glass window lets you monitor the oil level, usually marked by a circular, typically red mark, helping you understand the upper and lower oil limits.

Need To Check the Air Compressor Oil Level

Checking the oil level in your air compressor is straightforward. Compressors usually come with a special oil window that’s easily accessible for both owners and technicians. Before checking the oil level, ensure the floor is flat and the compressor is stable. Never start the compressor if there appears to be too much or too little oil in it. If the oil level appears abnormal, consider getting your compressor serviced.

Frequency of Changing Air Compressor Oil

The frequency of changing your compressor oil can be compared to how often you change oil in your car. For regular DIY users who don’t use the compressor frequently, it is recommended to change the oil every 6-12 months, or as guided by the compressor manual. Industrial compressors used continuously might need an oil change every 300 hours of operation.

Takeaways

It’s worth noting that checking the oil level regularly is crucial. Ensure the compressor is stable and on a flat surface before checking the oil level. If you notice the oil level is too high or too low, get your compressor serviced.Be sure to follow the correct steps and guidelines, and never overlook the importance of maintaining the right oil level. Remember, not all air compressors require oil, and it’s crucial to understand the type of your compressor. Keep these tips in mind, and your compressor should run smoothly for years to come!

Frequently Asked Questions

1. How much oil do you put in an air compressor?

Check your compressor manual for guidelines on checking/adding oil. Typically, the oil level should be in the center of the sight glass marker. If the oil level is below this, your unit needs more oil. If it’s above, you’ve added too much.

2. What is the best oil for an air compressor?

Standard air compressor oils with a mineral oil base are ideal for light to medium operations. Synthetic air compressor oils are recommended for continuous, heavy-duty operations. They are better at preventing overheating and promote quiet operation.

3. What happens if you put too much oil in an air compressor?

Overfilling your compressor’s oil reservoir can cause functional issues, such as excessive carry-over, which can be costly and potentially damaging to other parts of your compressor. Always ensure the oil level is correct to avoid such problems.

Before changing the air compressor oil, it’s essential to identify these four crucial components:

- Oil Fill Port: This is where you pour in the new oil. It’s usually higher than the oil drain port.

- Sight Glass: It lets you check the oil level. Make sure to keep the oil level to the center of the red dot on the sight glass.

- Oil Sump: Located inside the compressor casing, this is where the oil resides. It’s crucial not to overfill it.

- Drain Plug: Removing this plug allows the oil to drain from the sump.

Shaleen is a Journalism postgraduate, and like every other gen-z, loves a good dose of humor, Italian food, fashion trends, and TV series. She is an acomplished author and expert in the field of air compressors. Shaleen discovered her passion for technical products and gadgets early in life, which drove her research and write about it.